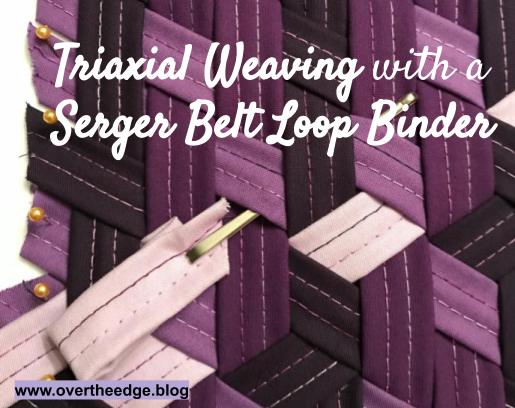

Triaxial Weaving with a Serger Belt Loop Binder

If you have a serger with a cover stitch and a belt loop binder attachment you are going to love this post, Triaxial Weaving with a Serger Belt Loop Binder. A new way to create quick and easy fabric strips for weaving into your own custom fabric! No more making fabric strips on the bias and no more burning your fingers while ironing the folded strips!

Serger Belt Loop Binder Attachment

Baby Lock has a specialty serger attachment called a Belt Loop Binder, which comes in two sizes (1.5” and ¾”). Other manufacturers may have something similar. The belt loop binder is designed to be used with a cover stitch.

I’ve seen it used to make belt loops, handles, straps, and bracelets. Belt loops and straps are very useful. But making your own woven fabric from these strips is way more exciting and is another perfect application for this attachment. And you don’t have to make bias strips for this weaving to work. You can cut strips by the width of the fabric (selvage to selvage), feed them into bias binder attachment on your serger, and quickly make fabric strips ready to weave into cool designs! This method is so much faster than cutting traditional bias fabric strips and standing at the ironing board pressing the edges under. And since it works on the cross grain, you don’t have to spend time creating the bias strips of fabric. I love my serger!!!

Modern Fabric Strip Weaving

Fabric strip weaving is becoming a popular activity. I first saw a bias fabric strip triaxial weaving project in a Sew News magazine (Feb/Mar 2017)

The article/project was titled “Take It or Weave It” was written by Tara Curtis, of Wefty. She invented a tool called the Wefty Needle to help make fabric strip weaving much easier. Bias fabric strips are made and then folded and pressed into bias tape. Then the bias tape is woven into fabric. Of course when I saw the project my first thought was “how can I use my serger to make this easier!”

Tools for Weaving

I purchased a set of Wefty needles from Tara. They work well for weaving ½” folded fabric strips and 1” folded fabric strips made with bias strips the traditional way. However, the Wefty Needles don’t work as well for serger belt loop binder strips. The tool was just a little too wide for the ¾” strips made from the 1.5” belt loop binder. It was hard for me to get through the tight weave of the third row of the triaxial weave. If the Wefty Needle was available in a ¾” or ⅜” it would be perfect for using with fabrics strips made with babylock belt loop binders!

I ended up using a bodkin (for inserting elastic or cord into a casing) to help me weave that 3rd row. The Wefty needle would have worked better than the bodkin if it were the right size for the ¾” strips. Recently, I found a ¾” elastic threader by Dritz that I am going to try on my next project. For other tools needed for fabric strip weaving see the Resources section at the bottom of the post.

Weaving Types

Basic or simple weaving occurs in 2 directions (biaxial at 90 degree angles to each other). Some forms of basic weaving you may be familiar with include plain weave, satin weave, twill weave, basket weave. Triaxial weaving occurs in 3 directions (triaxial 60 degree angles to each other). You can make some really nice weaving projects with basic weaving, but I think there is something special about triaxial weaves. I have included some links to resources about weaving at the end of this post.

Jen’s Triaxial Weaving with a Serger Belt Loop Binder

The Sew News article did inspire me to try fabric strip weaving, even though I didn’t make the basket that was in the article. Following the basic instructions in the article, I created my triaxial weave using fabric strips made on my serger with the 1.5” belt loop binder attachment. I then used the new “fabric” to construct this bucket from Simplicity pattern 8859 (I did make a few minor modifications to the pattern for this fabric basket/bucket). I really enjoyed triaxial weaving so I had to do more of it. After one project I was hooked!

I really like the look of “stars” in triaxial weaving, so I decided that would be my next project. I figured out how to weave the stars after some trial and error and a little research on the internet. It probably would have been faster to purchase a pattern from Wefty to show me how to do it, but I wouldn’t have learned so much about weaving! Like with the fabric bucket project, I used the 1.5” belt loop binder attachment to make my strips. Then I made a pillow from the triaxial weave “stars” fabric that I created. This pillow was constructed on the serger, including using a cording foot to install the zipper. The pillow pattern I created may be included in my blog in the future.

Tutorial – Setting Up and Using a Serger Belt Loop Binder

I created a tutorial and a video to help you be successful using the belt loop binder attachment with your serger. You will find the links below.

Hope you enjoyed learning about triaxial weaving with a serger belt loop binder!

Resources for Fabric Strip Weaving

Here are a few internet sites and youtube videos for you to check out if you would like to learn more about the process of weaving with fabric strips.

Tara Curtis of Wefty

Website: www.weftyneedle.com

https://weftyneedle.com/blog/2016/8/26/tools-for-weaving-updated

Tumbling Blocks Mad Weave Tutorial Video by Wefty – https://youtu.be/6xlUirFs0Kg

Mathew Boudreaux of Mister Domestic

Website: www.misterdomestic.net

https://misterdomestic.net/2017/12/29/fundamentals-of-fabric-weaving/

Fundamentals of Fabric Weaving Video by Mister Domestic – https://youtu.be/vlGt5Mxs2M0

If you want to get Tara’s fabric bucket pattern from the Sew News magazine, click on the link below to get more information.